Release Date:2024-01-17 17:13:51

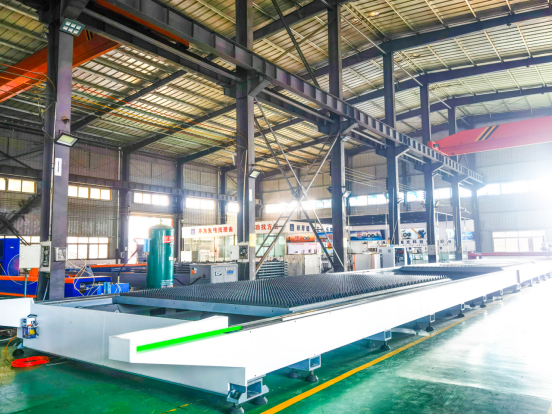

To do a good job, one must first sharpen one's tools. In modern times, it can be metaphorically said that in order to produce better, one must first prepare better processing equipment. In an environment where industrial production demand is increasing, the coexistence of quality and efficiency is a key factor for industrial success. Today, a 15000W single laser cutting machine from Wuhan Leite Laser was successfully delivered to an ecological and environmental protection company. In today's advocacy for ecological environment protection, the demand for environmental protection equipment is constantly increasing. Laser cutting machines can reduce the burden on enterprises and greatly improve production efficiency.

In the ecological environment protection industry, there is a high demand for mechanical equipment processing and high precision requirements. Only by improving production efficiency can we stand out in the industry while ensuring quality and accuracy. The cooperation between 15000W laser equipment and the ecological environment protection industry will greatly improve the production efficiency of ecological environment protection series products. The Leiter Laser 15000W laser cutting machine can process metal sheets up to 60mm, meeting the requirements of most ecological and environmental protection machinery. Fast and high-precision processing enables the sheet to be formed in one go without the need for subsequent grinding and polishing. The accuracy can be controlled within ± 0.03mm, reducing assembly processes and promoting a leap in processing efficiency for ecological environment protection enterprises.

In the past, customers had limited cutting production capacity and relatively slow production efficiency, mainly reflected in the manufacturing of sheet metal parts. After introducing a 15000W single platform laser cutting machine, the cutting process has been upgraded. What used to require a whole process to complete now only requires one step, greatly reducing processing time and greatly improving the production capacity of sheet metal parts. Production efficiency and excellent cutting accuracy will also provide customers with better solutions and more technological possibilities.

The advantages of laser cutting machines in the field of sheet metal cutting are beyond doubt. Laser cutting has become a solution for metal material cutting due to its high processing efficiency, high precision, good cross-sectional quality, and low dust. Widely used in industrial production in various industries. The addition of Wuhan Leite laser cutting equipment will provide stronger support for ecological environment protection enterprises with its good processing efficiency and precision. Enable enterprises to fearlessly handle peak orders in large quantities and meet their processing and production needs.